Search This Supplers Products:Lithium BatterySodium BatterySodium Battery CellHome BatterySolar GeneratorRv Battery&Marine Battery

Which type of battery can be used in a robots or electronic device?

sourceGoogle

publisherKayla He

time2023/11/29

- This study deeply explores the application of lithium iron phosphate batteries in AGV robots, through analysis of its battery performance, charge and discharge characteristics, etc.

Whether it is a factory or an individual, energy management is more refined and clear. E-lary adheres to the principle of never-ending research and innovation and is committed to the design and development of robotic smart batteries for AGV.

The design of E-lary smart robot AGV batteries can not only meet the requirements of handling robots, but can also be extended to industrial large-scale handling AGVs, industrial forklifts and other fields. Able to complete material handling tasks efficiently, accurately and flexibly. Next, follow us to learn what smart robot lithium batteries are, explore the advantages they bring, discover their diverse applications, and uncover the secrets behind ensuring their superior performance

Elary Smart Robot AGV Lithium Ion Battery

What is the E-LARY smart robot lithium battery pack?

Robot lithium battery pack refers to a battery solution specially designed to meet the special application fields of intelligent handling robots. Based on the scene characteristics of long-term operation and high power output of handling robots, E-LARY's main research and development focuses on two aspects: low power and fast charging. Make lithium batteries more standardized, informatized, digital, and intelligent to achieve multi-dimensional safe interconnection and data interoperability. Wireless charging technology provides high-quality, highly stable, and highly reliable power support

Optimize design:

The flat design of the E-LARY intelligent handling robot lithium battery makes the battery lighter and can be seamlessly connected to the robot structure. Ensures efficient use of available space without impacting performance.

Enhanced energy density:

E-lary's robot battery is distinguished by an exceptional fast-charging capability, boasting an impressive 8000 extended cycles. With a nearly 2.5C charge rate and a discharge rate of 2, it delivers increased power and energy density in a package that is both compact and lightweight.

What are the advantages of E-LARY smart AGV robot lithium battery?

The benefits of encapsulating lithium batteries for intelligent robots go well beyond the domain of robotics. Let's delve into several pivotal advantages that position these batteries as transformative elements within the automation sphere.

Efficiency and performance

E-LARY intelligent robot uses 21700 cylindrical full-ear fast-charging lithium-ion battery. These batteries can achieve higher charging speeds and have a wide operating temperature range, with a capacity retention rate of 75% at low temperature -30°C.Versatility across applications

While initially crafted with robots in mind, these batteries showcase impressive versatility. Their adaptability becomes evident as they can also be used in a variety of automation systems (such as AGVs and forklifts) to better meet the cost-effective needs of factory equipment.

Longer cycle life

Intelligent robot encapsulated lithium batteries generally have a longer service life than traditional batteries. It has lower maintenance costs and can also minimize the impact of frequent battery replacement on the environment.

Are there other application areas?

The lithium battery developed and designed by E-LARY for robotic systems finds application in various scenarios as well

Industrial automated guided vehicles

AGVs are the best handling equipment when it comes to handling management in modern warehouses and manufacturing operations. Through the high energy density of E-lary lithium iron phosphate AGV lithium batteries, AGV electric vehicle operation becomes faster and more economical, while greatly reducing errors. Improve overall production efficiency.

Forklift

For material handling in warehouses and distribution centers, these batteries find utility in forklifts as well. The robot lithium batteries are interchangeable across diverse automation equipment, resulting in a reduction in labor costs.

How to ensure excellent performance?

E-lary's robot AGV batteries results from a synergy of technological advancement and meticulous experimental research. Let's delve into these pivotal factors influencing battery performance.

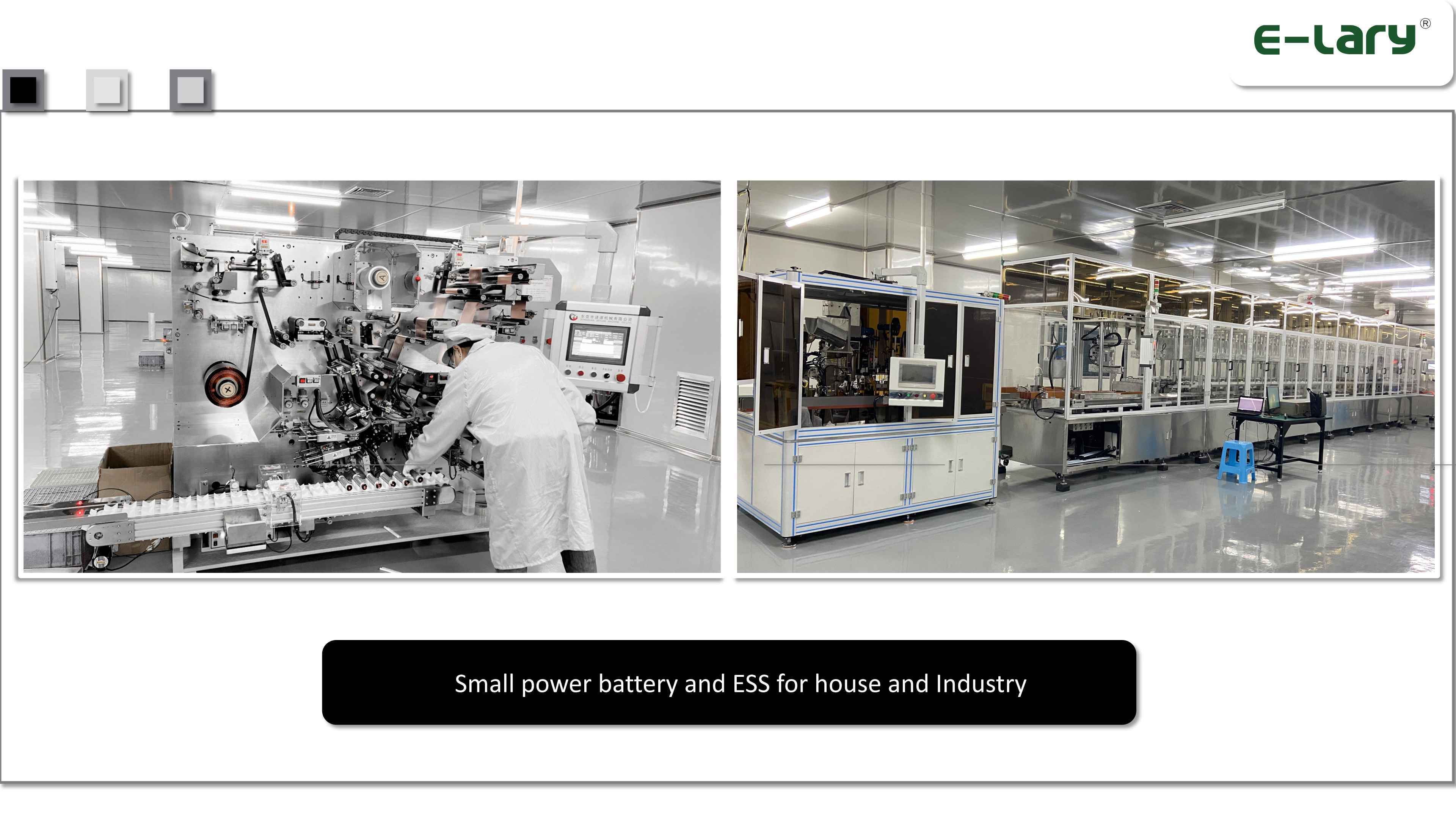

Quality Manufacturing:

At the heart of superior battery performance is quality manufacturing. The precision-made 217000 battery uses high-quality materials and advanced manufacturing processes.

Advanced Battery Management System (BMS):

The E-lary robot battery covers the built-in BMS integrated system, which is used to effectively monitor and optimize the performance of the lithium battery, and adjust the temperature, voltage, and current through the system to ensure the safe operation of the battery. It should be noted that the working environment temperature of the battery and the working environment temperature of the product should not exceed the upper or lower limit of the rated temperature, and the product should be used within the voltage range.

Regular Maintenance and Monitoring:

User maintenance programs and ongoing monitoring of battery condition are also important to extend battery life and maintain optimal performance. For example, regular wear checks, battery management system calibration, etc.

Adaptive Charging Algorithm:

The battery's adaptive charging algorithm will optimize the charging process, improve efficiency and extend the overall life of the battery. These algorithms flexibly adjust charging parameters based on variables such as temperature and charge level to help maintain the charging cycle

Conclusion on Robot AGV Battery

The advent of E-LARY's robotic packaging of lithium batteries marks a revolutionary shift in automation and energy storage. From designs tailored for robotic applications to versatile applications in AGVs, forklifts, and industrial drones, these batteries have the potential to redefine the landscape of automation technology. By leveraging their advantages, industries can enhance the efficiency and performance of robotic systems while contributing to a more sustainable and environmentally friendly future. As we navigate the ever-evolving frontier of automation, robot-packed lithium batteries serve as a beacon of innovation, illuminating the path toward a new era of intelligent and energy-efficient technology.

Welcome To Our Discussion Group For E-lary Battery.

Be respectful, be constructive, stay on topic, support other commenters, and report bad behavior.

For more insights on robot battery, please leave a comment